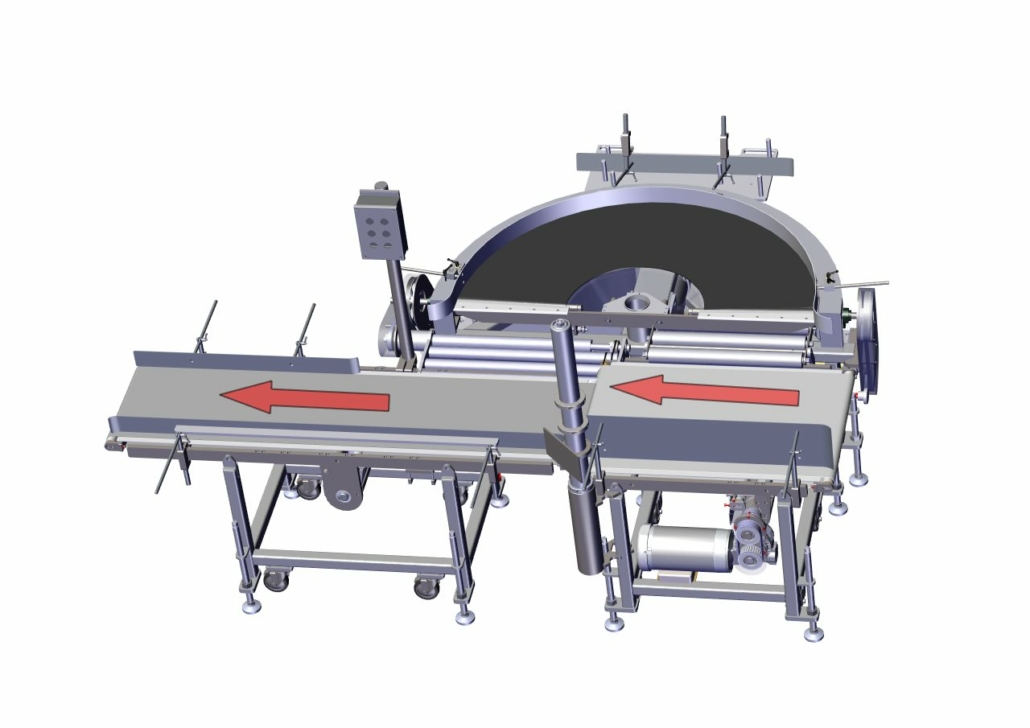

Carton Turn System

CARTON ORIENTATION FOR CASE PACKING EASE

The WSI Global Carton Turn System (CTS) can reverse the orientation of finished, folded cartons prior to entering an automatic case packer – enabling cartons to be packed with the glue flap up or down.

The CTS is positioned between the gluer and the case packer. If the shingle is to be reversed, the stream of cartons is redirected around the U-shaped conveyor. When exiting the discharge conveyor, the cartons is reversed. The carton’s leading edge becomes the trailing edge and the glue flap is re-positioned to the opposite side.

When carton reversing is not required, the short transverse conveyor is used as a bypass conveyor and cartons move straight through from the gluer to the case packer.

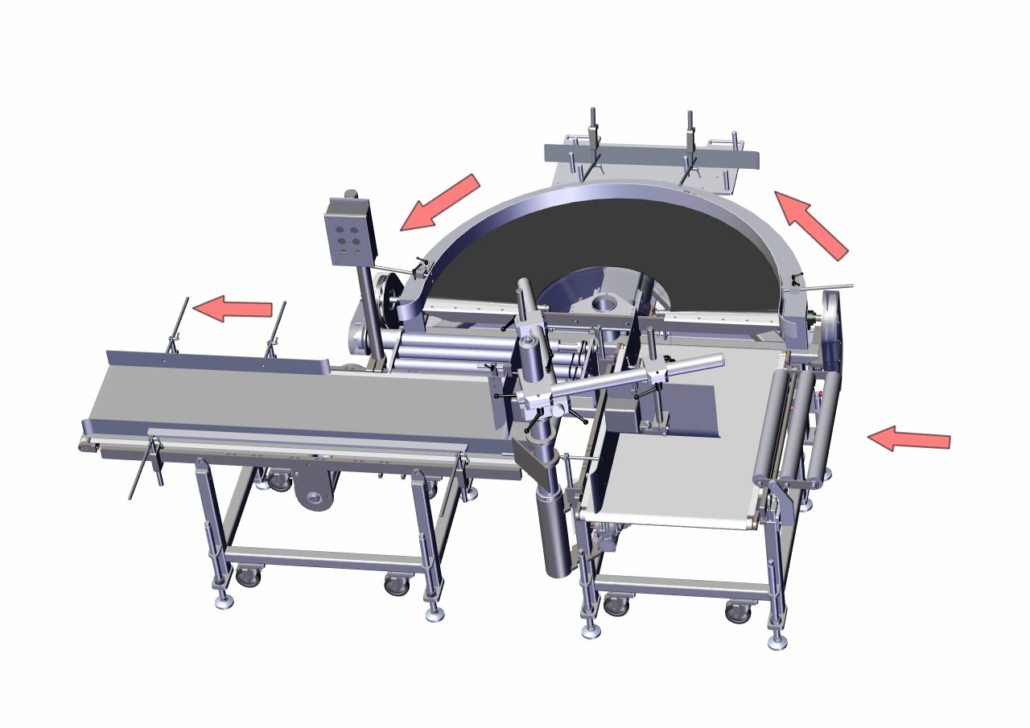

Carton Turn System Operation

Shingled cartons enter the Carton Turn System from the gluer’s delivery apron and move onto a short, transverse conveyor. The transverse conveyor directs cartons 90-degrees to the right to a powered U-shaped conveyor.

Cartons continue around the U-conveyor then cross a set of powered rollers and move onto a second transverse conveyor where they move 90-degrees to the right to the case packer’s in-feed conveyor.