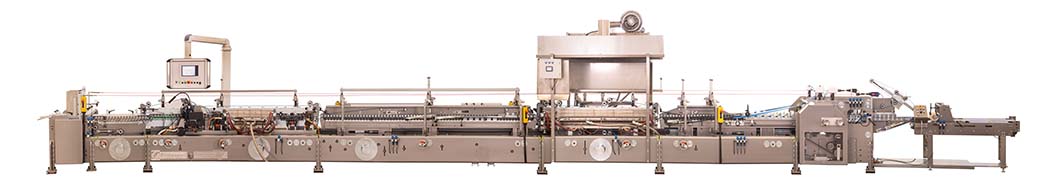

LF – IV 700/CH

The new International Switzerland LF-IV 700/CH is designed for the converters where floor space is a prime commodity. With a total length from feed to delivery apron of approximately 16,5 meters this Sealer will fit nicely into the space currently occupied by your old International LF-B Sealer.

The belt speed provided by the LF-IV of 700 meters per minute offers a production volume over 100’000/hour of one liter pure pack or Combibloc style cartons. The production speed makes, in general, 85 % of the quoted belt speed depending on type of substrate, blanks spacing and if the substrate is foil laminated or not (foil laminated substrate may produce lower output compared to unlaminated substrate).

The International/Switzerland LF-IV 700/CH Combibloc machine with combined production featuring Gable Top or Combibloc style cartons is equipped with an additional pre-fold section allowing pre-breaking of all the scores. Comfortable flexibility combined with a generous size range from mini-cross to one-gallon containers easily substitutes the size range of the previous International LF-B machine. Many other features were added such as low dust, high production hygiene, special bleed proof bearings, water-cooled burners, friction-free operation, and high precision skive-hem-pre-seal. As well as inline quality assurance providing the security of automatic inline packing dictated by the high production of the Sealer, especially when interfaced with automated packing not allowing visual inspection anymore.

Exclusive new main features

- New c-shaped steel frame profile adding highest stability to side frames

- New increased belt speed (mechanical speed) up to 700 meters per minute

- More compact machine design

- Watercooled main burners

- Watercooled hem burners

- New gas-air mixing system with recipe recall

- Dynamic register bar for dust elimination

- All folding operations dynamic with belts

- New reverse belt technology oversized drive drums

- Main drive located in center of machine

- New reverse belt drive allowing fast belt changes

- Large hand wheels allowing fast carrier displacement

- Large size range from mini-cross to 5 liter containers

- Small carton features in final fold section

- Drum drive technology guaranteeing absolute back lash free production

- New line engineering providing maintenance free line

- State of the art fortuna csp-iv hem pre-seal equipment with touch screen monitor

- Leary quality assurance system with high speed ejector

Standard Machine Sections and Configuration

- Feeder

- Side register

- Pre-fold

- Skive / hem

- Preseal

- Burners

- Final fold

- Delivery

- Stacker

- Water conditioner

Machine is capable of achieving the belt speeds up to 700 meters per minute – the production speed makes, in general, 85 % of the quoted belt speed depending on type of substrate, blanks spacing and if the substrate is foil laminated or not (foil laminated substrate may produce lower output compared to unlaminated substrate).