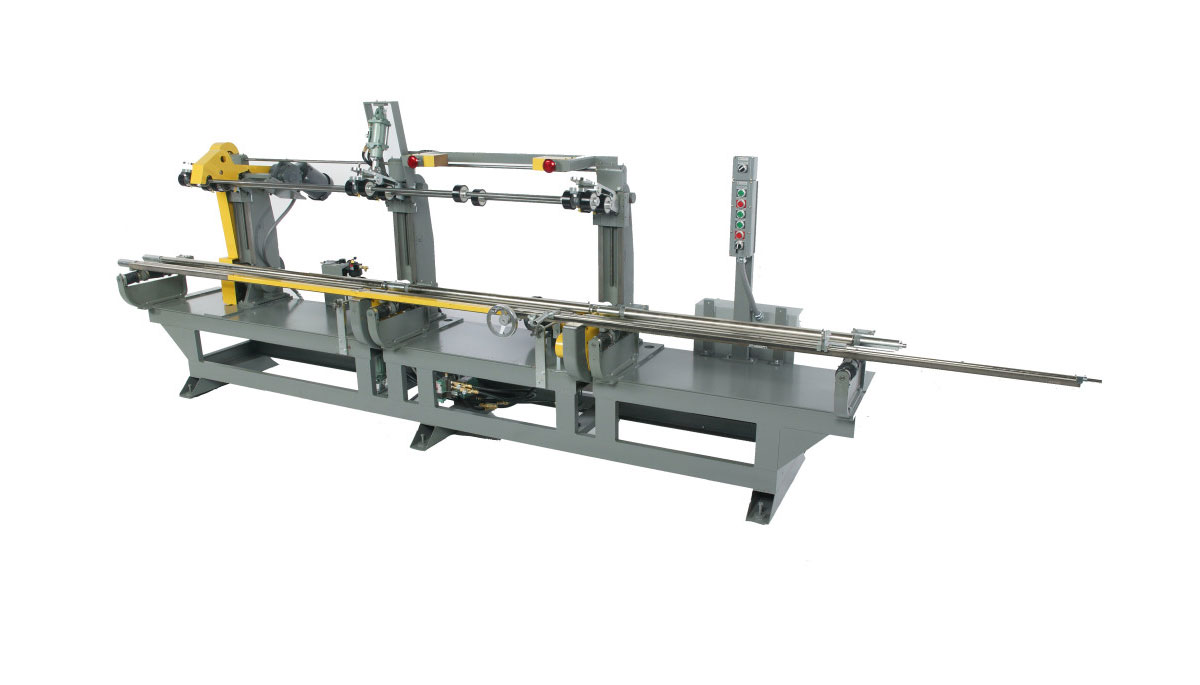

Core Saws

Ragged-edge cores and interlocking rolls become a thing of the past with a WSI Global Core Re-cutter. A special, heavy-duty saw blade provides smooth, uniform cuts time after time. An adjustable bed and a 2-way air-valve switch located at the operator’s station allow for a range of core diameters to be cut.

WSI core recutters are designed for use on heavy-wall, paper tube cores with wall thickness up to 1-inch (25.4 mm). Standard models are available for core diameters ranging from 2.5-inch OD to 26-inches OD. Other combinations of maximum recut and parent core length can be provided upon request.

CR-100, CR-200 and CR-300 series

Model CR-100, CR-200 and CR-300 recutters use the idler roll / rider roll principle. The core is held between two adjustable, rubber-coated idler rolls and a driven rider roll. The rider roll is air-actuated to securely hold the core during the cut. The cut is made from below the rotating core.

CR-70 series

The CR-70 is an intermediate model core recutter and uses a cradle roll / rider roll principle. The core is driven by two, lower knurled cradle rolls. The upper rider rolls act as the idlers.

Three standard models ….. the CR-70CR-70-L, and the CR-70-EL ….. provide a selection of machines to handle maximum parent cores lengths from 160-inches to 280-inches.

Specifications

Maximum parent core sizes, maximum recut lengths, and core diameter ranges

| Model | Re-cut length (max) | Parent core length (max) | Core OD Range |

|---|---|---|---|

| CR-70 | 84″ | 160″ | 2.5 to 9.0 |

| CR-70-L | 120″ | 220″ | 2.5 to 9.0 |

| CR-70-EL | 120″ | 280″ | 2.5 to 9.0 |

| CR-100 | 96″ | 200″ | 3 to 16 |

| CR-200 | 96″ | 200″ | 3 to 22 |

| CR-300 | 96 | 200″ | 3 to 26 |

| CR-120 | 120 | 220″ | 3 to 16 |

| CR-220 | 120 | 220″ | 3 to 22 |

Dimensions are in inches.

Maximum wall thickness is 0.75 inches for CR-70, CR-100, and CR-200 series.

Maximum wall thickness for CR-300 is 1.0 inches.